Good is not good enough

What is important for good tool design? We interviewed product designer Timo Kuhls from Festool.

But how do you produce a product that impresses both with its unusual shape and supreme functionality? We asked product designer Timo Kuhls.

Timo Kuhls

Festool product designer

Timo Kuhls has been working in the product design department at Festool since 2008. In an interview, he tells us how perfect ergonomics and functionality are achieved at the Festool products.

The compact sanders are among the most recent additions to the Festool family. What is the biggest challenge for you?

With our electric power tools and pneumatic tools, the general requirements are becoming increasingly complex, in terms of the technical engineering, the structural design and even the creative design. That is particularly true when it comes to the compact sanders. They need to be very powerful, but at the same time lightweight, easy to handle and ergonomically perfect. And the biggest challenge of all is to build precision tools that are also extremely robust and durable.

Users notice straight away whether a new sander works perfectly and sits nicely in the hand. Are there also ingenious product features that users don’t notice?

All devices have an inside and an outside. For example, the housing is generally made of plastic half-shells. From the outside, first and foremost these shells have to be functional and ergonomically correct, as well as reflecting the Festool design language. The insides of the shells have to satisfy completely different requirements, because they play a major part in allowing us to accommodate the electronics and mechanics, the transmission and the motor, as compactly as possible in a very confined space.

The brushless EC-TEC motors, for example?

Exactly. This is not just a motor but an extremely intelligent drive concept. EC-TEC works without carbon brushes, making it maintenance-free. When the tool approaches the critical range, EC-TEC automatically reduces the electricity supplied and the power output. These are functional product features that pay off directly for the customer: powerful and maintenance-free with a service life that’s up to ten times longer and minimal energy consumption.

And there’s the fact that virtually no Festool products are stand-alone products but always have to work as part of a system.

That’s right. And that plays a crucial role in every new product and in any further development. But let’s stick to compact sanders: there are the eccentric sanders, the delta sanders and the orbital sanders. Each sander stands on its own, but they were developed together as a family. The system includes the corresponding accessories and consumables. To ensure clean work, each machine can have a handy dust collection bag attached to it, or even one of our CLEANTEC mobile dust extractors. And each device also has a matching storage system in a SYSTAINER. In short, we develop and design everything as part of a system.

How much do you think and design from the point of view of the user?

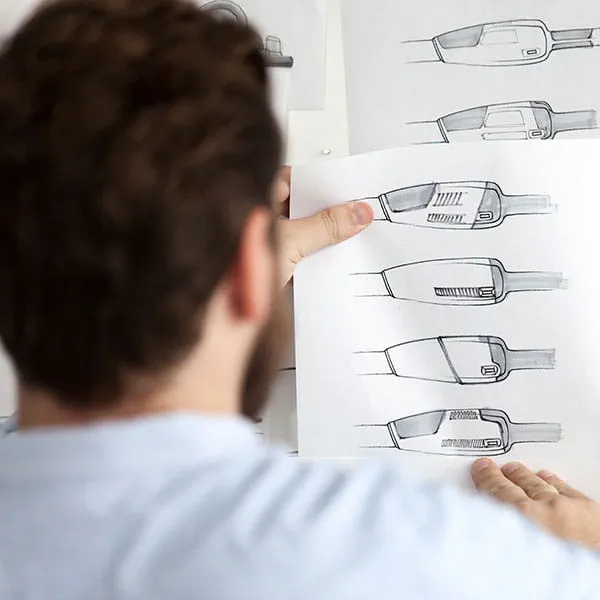

When we are working, there is always a user sitting on our shoulder – or an imaginary one, at least (laughs). But seriously, we have a lot of long-standing customers. And with new customers, too, the expectations are very high. That’s why we can’t afford not to see things from their perspective. With every new product idea, we ask ourselves what users need and how we can make their work easier. Asking ourselves this question results in very specific decisions when it comes to the design and configuration of a tool.

Who makes these decisions?

They are joint decisions made by the development staff involved in the team. Interior and exterior, ergonomics, function and mechanical design are all so tightly intertwined that they cannot be viewed in isolation. Which is why it is so important that I work closely with colleagues from development, application technology, construction, production and product management during the product design process. Each person contributes their expertise and experience. And as a team we are always agreed that, for us, good is not good enough.

What makes Festool product design different?

The product design always feeds directly into the exceptional Festool product features. We have also succeeded in developing a clear, timeless, easily understood and at the same time emotional product language. From our point of view, this clarity and continuity is extremely important, and is associated with a high recognition value. After all, each individual product represents the values Festool stands for.

The legendary product designer Jonathan Ive succeeded in giving Apple products something which triggers a ‘must-have’ response, so to speak. Does that work with power tools as well?

Our tools are not consumer or lifestyle products. Nevertheless, the status of our products does play an important role. To the initiated, a craftsman who works with Festool equipment is seen as a professional with the highest standards. In that respect, the product also says a lot about its owner. Although we cannot compare ourselves to Apple, it does make us a little proud.