Tintelijn

An inspirational painter's collective

Jan Van de Gracht had a fine line in mind when he named his new painting company Tintelijn in 1989. But the painter from Ghent has never toed the line. He has done things differently right from the word go: Out of conviction, with vision and – as today shows – with considerable success.

Welcome to Ghent, the city of flowers in Flanders! We were told that, on Sundays, there is a magnificent flower market here in Kouter Square. But we are not here for pleasure, and we are not meeting the people behind the painting company Tintelijn until Monday morning in any case. In the eastern district of Sint-Amandsberg, we reach our destination and turn into the entrance, where it is actually green and in bloom – a pleasant surprise. "Our company premises, which we spent a lot of time renovating and expanding a couple of years ago, actually used to be a nursery with greenhouses," Bram Klüssendorf explains, welcoming us. Tintelijn has been based here since 2018. The workshop is equipped with the best machinery, and Tintelijn has built a modern, eco-friendly passive building for the shop. Instead of flowers, there are now paintings in all colours and shades.

The fact that things have grown here that you would not expect to see in a conventional painting business does not appear to be a coincidence. And this is true not just since 2018, but actually for the past 30 years. You have to go back that far to understand where Tintelijn is today – and whose child this extraordinary business is, which was established by Jan Van de Gracht in 1989. It would be easy to think of him as part of the "flower power" generation, but he was actually more of a "rebellious punk" in his younger years, or at least that is how Van de Gracht describes himself. He rebelled against everything that other people viewed as normal. He dropped out of school, completed an apprenticeship as a painter, was annoyed that, as a newly qualified tradesman, he was treated as "inferior," and took an interest in alternative life plans, in ecological concepts and sustainable business models. He went to Berlin, returned to Ghent and became his own boss:

The best way to start doing things differently. Together with a friend, Jan Van de Gracht founded the painting company Tintelijn. A short time later, a third partner came on board. After a few years, they decided to go their separate ways and Jan became the sole partner. But he had never wanted to be a boss. "Tintelijn was created as a collective – and that's how it should remain," stresses Van de Gracht, "as that's one of the pillars that our company is based on: Respect for each another, respect for health and respect for our environment." Around the turn of the millennium, Hans Mathys and Bram Klüssendorf joined as partners, with Peter Coudenys and Michael Fockedey coming on board a few years after that.

"Every employee ought to feel like a trendsetter. They each bring their own experience, views and skills to the table."

Bram Klüssendorf

Thinking ahead. Ecological pioneers with valuable expertise.

The five partners are still with the company and form the management team at the collective. All employees who have been at Tintelijn for more than three years can take part in the general meeting by purchasing a share. Their vote carries the same weight as the partners' and they are included in decision-making processes at Tintelijn, which means that they can help to shape the future of the company. And they benefit from direct profit participation at the end of each financial year. So, are the employees more motivated because they are essentially working for their own company? Jan Van de Gracht believes so: "Everyone really identifies with the company. Our employees know what we are about and what they are working for. This means that they are more prepared to go the extra mile as well."

Jan Van de Gracht was often laughed at early on for doing things differently and looking ahead. For example, at a time when no one was interested in environmental issues, he decided to use environmentally friendly materials and techniques. He gradually hired carpenters because he recognised that both the company and, above all, its customers benefited from having multiple trades and skill sets under one roof. As an ecological pioneer, Tintelijn has been working with sustainable natural paints, lime plaster, environmentally friendly insulating materials and linoleum for years. "More and more professionals and DIYers were coming to us looking for high-quality, environmentally friendly products," Bram Klüssendorf recalls. "So we decided to set up a shop in 2006 where, as well as selling environmentally friendly paints and construction materials, we could also pass on valuable expertise in this area to customers and colleagues."

Nowadays, organisations like Tintelijn are all the rage. "Every employee ought to feel like a trendsetter. They each bring their own experience, views and skills to the table," says Bram Klüssendorf. On projects, employees take it in turns to be the supervisor. This way, they learn how to lead a team, speak to customers and take responsibility. The range of services that Tintelijn offers is extremely broad and, as mentioned, includes various trades: Installing skylights, walls and floors, fitting doors, plastering walls, building fitted wardrobes, and filling and painting everything.

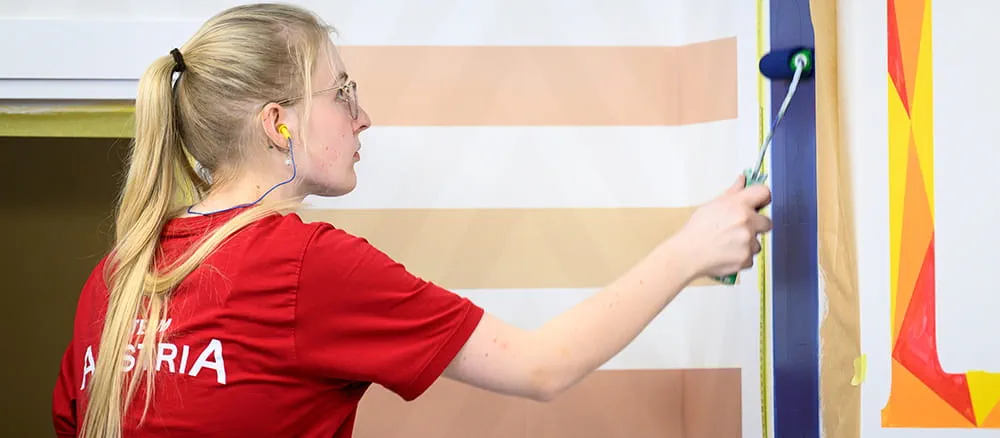

Inspiring: The painters at Tintelijn love what they do.

This is reflected in their work and their customers' appreciation. The aim is not to impress customers with exceptional quality, but to enthuse them and get them excited about it. That is what Jan van de Gracht firmly believes. And that is what his company has made "big", as he says. When measured in terms of the Tintelijn team's knowledge and skills and the variety of painting techniques and materials that they have mastered, their enthusiasm knows no limits. Their wealth of expertise ranges from traditional painting and stucco work on listed buildings to ecological solutions for modern new builds. "The customers who come to us know what we stand for and what we can do. We are not just contractors doing a job – we are advisers too. That makes our work so much more varied and exciting," says Jan Van de Gracht.

"Our employees know what we are about and what they are working for. This means that they are more prepared to go the extra mile as well."

Jan Van de Gracht

Doing it better.

Professionals with experience and passion. In the workshop, Sam Kerckaert is preparing two stucco elements for a listed town house with plans that date back to 1878. Using a template, he marks the profile of a piece that needs to be replaced on the façade. "Façade renovations are always really exciting," says Kerckaert," "as you can't get a complete overview of the condition of the façade and work out the best approach until the scaffolding is up."

We discover what he means by that the next morning on the construction site. Four people are working side by side on the render, the moulding, the windows requiring renovation and the front door. Cracks in the façade are scraped out and then filled with an embedded reinforcement fabric. "We always try to preserve the façade in its original state. Where possible, we use environmentally friendly render like lime mortar and breathable silicate paints," explains Sam Kerckaert. The oil-based paints used for the front door and the moulding are based on the original colour formulae.

"Festool machines are indispensable as far as we're concerned, both in the workshop and when working on site," says Bram Klüssendorf, who has accompanied us to the construction site. The Festool cordless sanders are perfect for preparing the substrate on doors, windows and soffits, while the Festool oscillator is used to carefully separate loose stucco elements. And because employees' health is important to Tintelijn, they are delighted to be able to try out the new Festool cordless extractor. "If you have to lug a cumbersome extractor through the small hatches and up the scaffolding to the moulding, you are tired before you've even got started," says Bram Klüssendorf knowingly. "The lightweight, manageable cordless extractors make a real difference here." So, when it comes to taking painting to the next level and doing it better, tools that make work easier are crucial. That's something that every member of Tintelijn understands and appreciates. Every single one. All together. Collectively.

Tintelijn cvba

The painting company Tintelijn in Ghent was founded in 1989. It is organised as a collective and has around 25 employees. Tintelijn has been pioneering environmentally friendly materials and painting techniques for over 30 years. In 2018, the company moved to a new, larger site and extended both the business and the shop, the latter of which has been operating since 2006.